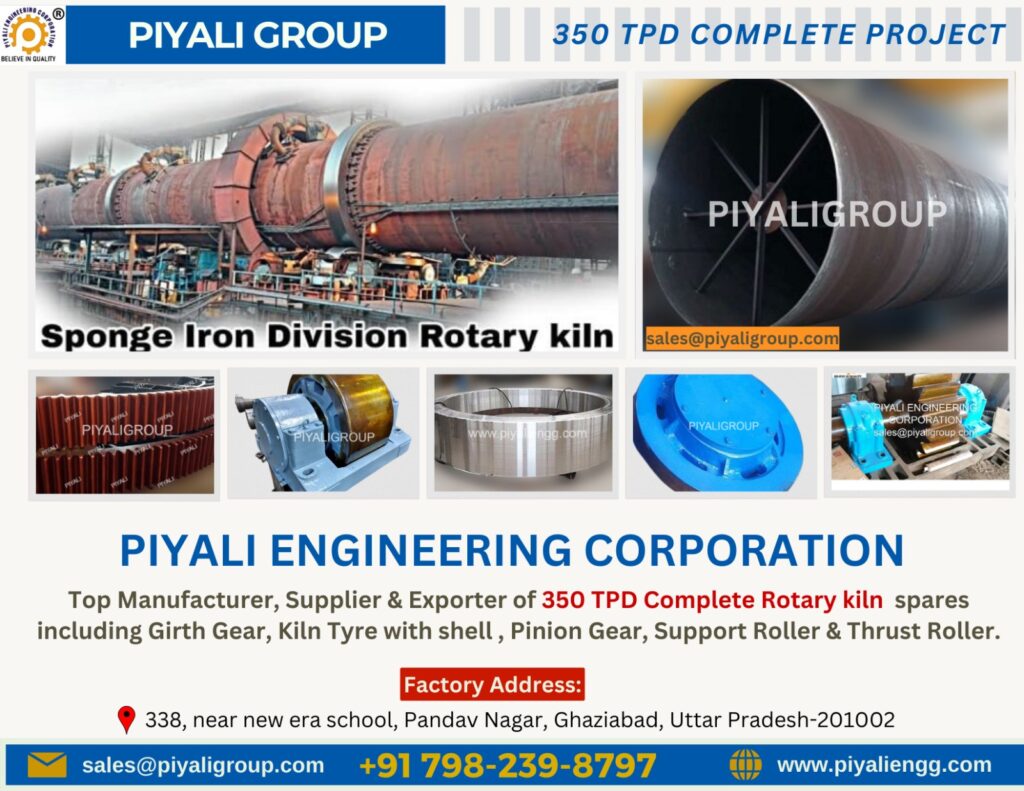

Rotary Kiln Cooler Parts

Sponge Iron DRI (Direct Reduce Iron) Base Rotary Kilns, Rotary Coolers, Rotary Drum Dryers, Steel Plant Kilns, Rotary Granulator, Roatry Coating Drum, Coal Dryer, Carbon Kilns, Petcoke Rotary Kiln, Lime Kilns, Sugar Mill Baggase Dryers, Slag Dryers Castings Equipments, Forging Equipments best manufacturer suppliers – PIYALI GROUP.

Rotary Kiln Girth Gear, Kiln Pinion, Kiln Pinion Shaft, Kiln Pinion Plummer blocks, Kiln Support Roller, Support Roller shaft, Support Roller Combined Bearing housing, Cooler Support Roller, Cooler Supporting Roller shaft, Cooler Supporting Roller Plummer blocks, Cooler Pinion Gear, Cooler Pinion with shaft, Cooler Girth Gear, Cooler Tyre, Kiln Tyre, Kiln Rim Tire, Kiln Girth Gear, Kiln Thrust Roller Assembly, Cooler Thrust Roller Assembly, Kiln Support Roller complete Assembly, Cooler Supporting Roller Complete Assembly Castings Equipments, Forging Equipments best manufacturer suppliers – PIYALI GROUP in India.

Request a free quote

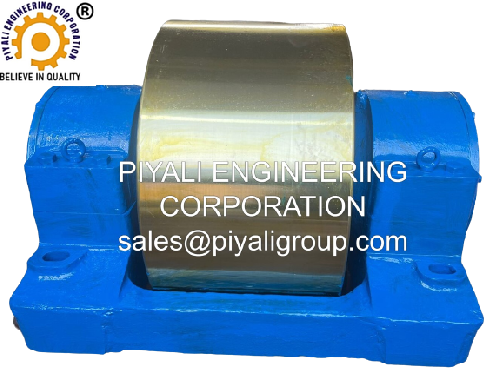

Kiln Support Roller Complete assembly

The rotary kiln support roller assembly is a critical component that bears the weight of the entire kiln, allowing it to rotate smoothly. It typically consists of a roller, shaft, and bearing seat with components like thrust rings and seals . They are vital for the efficient operation of rotary kilns in various industries like cement, chemicals, Sponge Iron, and power Plants etc.

Kiln Hydrulic Thrust roller Assembly

A rotary kiln thrust roller assembly controls the axial movement (forward/backward) of the kiln shell. Located near the large drive gear, it uses rollers and a hydraulic system for precise positioning and stability, crucial for optimal performance . These assemblies are essential in cement, lime, and other industries that rely on rotary kilns.

Rotary Kiln tyre with shell welded fitted

A rotary kiln tire is a thick, steel ring encircling the kiln shell. It sits on support rollers, allowing the kiln to rotate smoothly. The shell is the long, cylindrical body of the kiln, often lined with fire-resistant bricks. Together, the tire and shell assembly bear the weight of the kiln and materials inside . This key component is vital for industries like cement, chemicals, and power generations.

Rotary Cooler support roller assembly

Rotary cooler support roller assemblies function similarly to those in rotary kilns. They bear the weight of the cooler drum, enabling smooth rotation. A typical assembly consists of a roller, shaft, and bearing housing with seals and lubrication systems . These assemblies are essential for efficient cooling of materials in cement, chemicals, and power plants.

riding ring (kiln tyre) / Path ring / live ring

The rotary kiln tyre, also known as a kiln ring or riding ring, is a massive, ring-shaped component that encircles the rotary kiln shell . The kiln tyre is a crucial element for the efficient and safe operation of rotary kilns in industries like cement, chemicals, Sponge Iron Plant, Steel Plant, Carbon Plants, Petro Coke Plant, Ceramic Industries and power generation etc.

Rotary kiln gear Pinion Shaft assembly

In a rotary kiln, the pinion gear with shaft assembly acts as the “engine” for turning the massive kiln shell. The pinion gear, a smaller gear, meshes with a much larger gear called the girth gear. Made of high-strength forged steel, these assemblies are critical for driving and controlling rotary kilns in cement production, lime processing, and other industries

Kiln girth Gear

The rotary kiln girth gear is a giant, ring-shaped gear encircling the kiln shell’s midsection . Made of robust cast steel, it meshes with a smaller pinion gear, driven by the motor. This transfers rotation, allowing the massive kiln to turn slowly and efficiently. Due to the immense pressure it bears, the girth gear is a crucial component for smooth operation and long lifespan of rotary kilns in cement, power, and chemical industries. Sponge Iron Plant Rotary Kiln Girth Gear, Cooler Girth Gear and Preheater Girth Gear for 50 TPD, 350 TPD, 600 TPD, Sponge Iron Plant Casting and Forging Equipments.

Kiln Girth Gear Spring Plate arm assembly

Rotary kiln gear spring plate assemblies are shock absorbers for the giant kiln girth gear. Made from high-flexibility steel, these spring plates sit between the gear and supporting structures . They absorb vibrations, compensate for misalignments, and distribute stress, protecting the gear from wear and ensuring smooth operation. These assemblies are vital for maintaining peak performance and longevity of rotary kilns in Sponge Iron Plant ( Steel Plant), cement, chemicals, and power generation.

rotary Kiln tyre

The rotary kiln tyre, also called a kiln ring, is a massive steel ring hugging the kiln shell . This key component bears the weight of the kiln and materials, transferring it to support rollers for smooth rotation. Made from high-strength, wear-resistant steel, it endures high temperatures and constant stress. Because of its vital role, the kiln tyre is essential for safe and efficient operation in Sponge Iron Plant, Steel Plant, Fertlizer Plant, Chemical Plant Tyre Ring, Carbon Plant Tyre Ring, Steel Plant 50 TPD to 900 TPD., cement, chemicals, and power generation.

+91 798 239 8797

Give us a call

sales@piyaligroup.com

Drop us a line

Who we are

Piyali Group is a global leader in manufacturing high-quality spare parts for rotary kilns. Since [founding year], we’ve been driven by the pursuit of excellence, providing solutions that keep your kiln operation smooth and efficient.

High-Quality Products: PIYALI GROUP known for manufacturing reliable and durable kiln components.

Fast Delivery Times: PIYALI GROUP known for prompt delivery to minimize downtime for customers.

Excellent Customer Service: PIYALI provide exceptional support to help clients choose and maintain parts.

Technical Expertise: Perhaps they have a team with deep knowledge of rotary kiln systems and parts.

Competitive Prices: PIYALI GROUP offer competitive pricing compared to other manufacturers.

Global Presence: we have a strong reputation and presence in the international market. Egypt, Jordan, USA, UAE, Sri Lanka, Canada etc.

Meet our staff

Shubham

Factory Manager

Raj Kumar

Global Sales

Neha Sehdev

Marketing Manager

Arvind Kumar

Plant Head

What our customers say

Our happy customers

Mr. Ranjan Roy

Procurment

Dear Mr. Kumar, your commitment and delivery schedule are outstanding. As per the review from our end user, Mr. Mahanty, your materials are performing very smoothly.

Mr. Akash Kumar Vinodiya

Raw Material Inspector

Good company. Good quality and well management.

Kishore Jha.

Raw material sourcing Head

As per our order to Mr. Raj Kumar, he executed our material within our time period on a priority basis. Kiln tire with shell in 2023. We have very happy working with the PIYALI GROUP.

Himangshu Sahoo.

General Manager

The people at PIYALI GROUP are professional and deliver quality work. I highly recommend it to other companies. Best wishes.